In the ever-evolving landscape of American manufacturing, innovation and technology continue to drive progress. One of the most impactful advancements in recent years has been the integration of robotic assembly into the manufacturing process. This transformation is not just a trend but a fundamental shift that is reshaping how American manufacturers operate and compete on the global stage.

The Rise of Robotic Assembly

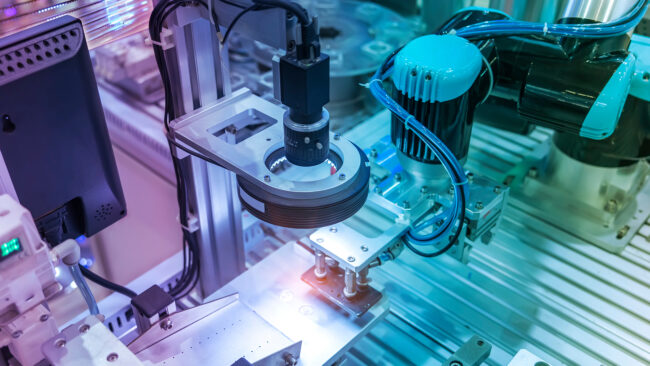

Robotic assembly, often referred to as industrial or robotic automation, involves the use of automated machinery, including robots, to perform various tasks in the production process. From precision welding to intricate part assembly, robots are increasingly becoming indispensable in American manufacturing.

1. Unmatched Precision and Consistency

Robotic assembly excels in delivering precise and consistent results. These machines can perform intricate tasks with a level of accuracy that surpasses human capabilities. This precision is essential in industries where product quality and performance are non-negotiable.

In sectors like automotive and electronics manufacturing, where components need to fit together perfectly, robots ensure that every piece is assembled flawlessly, reducing the margin for error and improving product quality.

2. Enhanced Productivity and Efficiency

Robots don’t get tired, and they can work tirelessly around the clock, leading to a substantial increase in productivity. They can complete tasks at a much faster rate than humans, ultimately leading to shorter production cycles.

The efficiency gains are not limited to speed alone. Robotic assembly is highly adaptable, allowing manufacturers to quickly reconfigure production lines to accommodate changes in product design or demand, resulting in a more agile and responsive manufacturing process.

3. Cost Savings and Competitiveness

While the upfront investment in robotic assembly systems can be significant, the long-term cost savings are substantial. By automating repetitive and labor-intensive tasks, companies can reduce labor costs, minimize waste, and optimize energy usage.

Additionally, automation helps American manufacturers remain competitive on a global scale. The cost savings, coupled with improved quality and efficiency, make products more cost-competitive in the international market, contributing to the growth and sustainability of American manufacturing companies.

4. Safety and Workforce Augmentation

The integration of robots into manufacturing isn’t about replacing human workers; it’s about augmenting their capabilities. Robots are well-suited to handle tasks that are dangerous, strenuous, or monotonous, reducing the risk of workplace accidents and repetitive stress injuries.

Furthermore, the use of robotic assembly necessitates a skilled workforce to operate, program, and maintain these systems. As American manufacturing companies invest in automation, they also invest in the development of a highly skilled and tech-savvy workforce, ensuring the industry’s continued growth and competitiveness.

5. Customization and Innovation

Robotic assembly is highly adaptable, making it possible to quickly switch between different products or configurations. This flexibility allows manufacturers to meet the growing demand for customized products and respond rapidly to market changes and consumer preferences.

Robotic assembly opens the door to further innovation. Companies can experiment with new materials, design concepts, and production methods, confident in the ability of robots to carry out intricate tasks with precision and repeatability.

Robotic assembly is at the forefront of a manufacturing revolution in the United States. It offers American manufacturers a competitive edge by increasing precision, efficiency, and cost-effectiveness while enhancing workforce safety and fostering innovation. As technology continues to advance, robotic assembly is set to play a pivotal role in the future of American manufacturing, enabling companies to lead the way in shaping the industry’s evolution and growth.