In the heart of modern manufacturing facilities, a silent revolution is taking place. Traditional assembly lines and production processes are being augmented by a new generation of workers – robots. These aren’t your typical robots, though, they are labor assist robotics systems, and they are changing the face of manufacturing as we know it.

The Rise of Robotics in Manufacturing

Before we dive into their impact, let’s understand what labor assist robotics are. These are specialized robotic systems designed to work alongside human workers, assisting and enhancing their capabilities in various labor-intensive tasks. Unlike fully autonomous robots that replace humans, labor assist robots are collaborative, complementing the workforce rather than replacing it.

Enhance The Efficiency and Productivity of Your Production Process

One of the most significant ways labor assist robotics impact manufacturing is by enhancing efficiency and productivity. Here’s how:

Heavy Lifting: In manufacturing, there are tasks that require immense strength and endurance. Labor assist robots are equipped with powerful actuators that can effortlessly lift and move heavy objects, reducing the risk of worker injuries and fatigue.

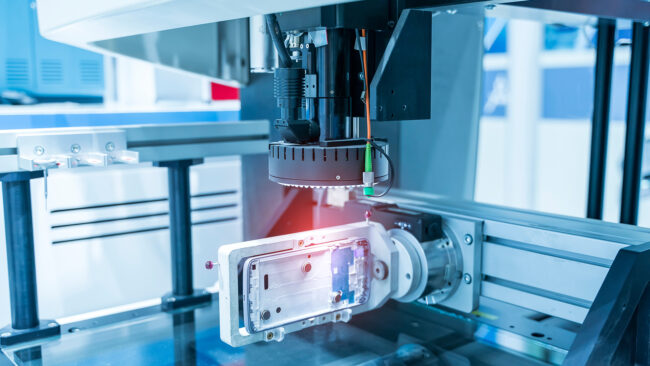

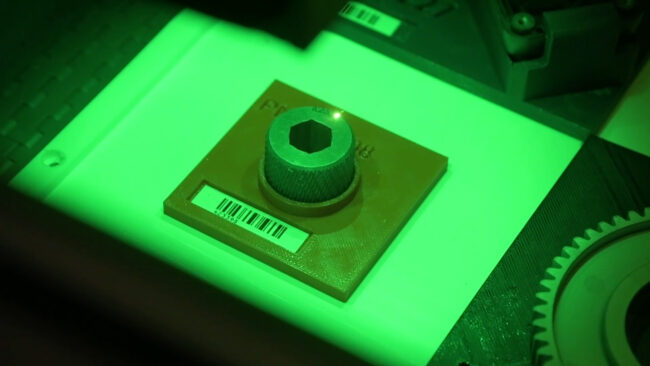

Precision and Consistency: Robots excel at performing repetitive tasks with impeccable precision. This means fewer errors and higher product quality. Whether it’s welding, painting, or assembling intricate components, these robots can do it with unmatched consistency.

Speed: Robots don’t tire, and they work at a constant speed, ensuring consistent production rates. This can be particularly beneficial in high-speed manufacturing environments.

Robotics Improve Worker Safety

Worker safety is a top priority in manufacturing, and labor assist robotics play a significant role in achieving this goal. They can take on tasks that are hazardous to human health, such as working in extreme temperatures, handling toxic substances, or navigating potentially dangerous environments. This minimizes the risk of workplace accidents and keeps workers out of harm’s way.

Skilling Up the Workforce

Contrary to the fear that automation would eliminate jobs, labor assist robotics can actually empower the workforce. These robots require skilled technicians to operate and maintain them. As a result, they create new job opportunities in the field of robotics and automation. Manufacturers are investing in training programs to equip their workforce with the necessary skills to work alongside these robots effectively.

Customization and Adaptability

Labor assist robots are highly adaptable. They can be programmed and reprogrammed for different tasks, making them suitable for a wide range of manufacturing processes. This adaptability means that manufacturers can easily reconfigure their production lines to accommodate changes in product design or demand.

Cost Efficiency

While the initial investment in labor assist robotics can be significant, the long-term benefits often outweigh the costs. These robots can significantly reduce labor costs, minimize production downtime, and decrease the need for rework due to errors. This cost efficiency makes them a wise investment for many manufacturing companies.

The Future of Manufacturing

As technology continues to advance, so will the capabilities of labor assist robotics. Future iterations may incorporate artificial intelligence and machine learning, enabling these robots to perform even more complex tasks and adapt to dynamic manufacturing environments.

Labor assist robotics are not the future of manufacturing; they are the present. They are changing the landscape by enhancing productivity, improving safety, and creating new opportunities for skilled workers. Manufacturers who embrace these technologies are positioning themselves for a competitive edge in the global market, ultimately shaping the future of manufacturing as we know it.