In the dynamic world of manufacturing, quality control is paramount. The demand for high-quality products that meet customer expectations continues to grow. Simultaneously, manufacturers are under constant pressure to improve efficiency, reduce costs, and minimize waste. To meet these challenges head-on, the manufacturing industry has embraced high-speed inspection and sorting systems. These cutting-edge technologies are reshaping manufacturing processes, ensuring product quality, and driving efficiency gains.

The Need for Speed

Manufacturers today operate in a fast-paced, competitive environment where efficiency is the name of the game. Traditional quality inspection methods are often slow and labor-intensive, making it challenging to keep up with the demands of modern production lines. High-speed inspection and sorting systems are designed to address this issue by significantly reducing inspection times while maintaining or even improving the accuracy of inspections.

Key Benefits of High-Speed Inspection and Sorting Systems

Enhanced Quality Assurance:

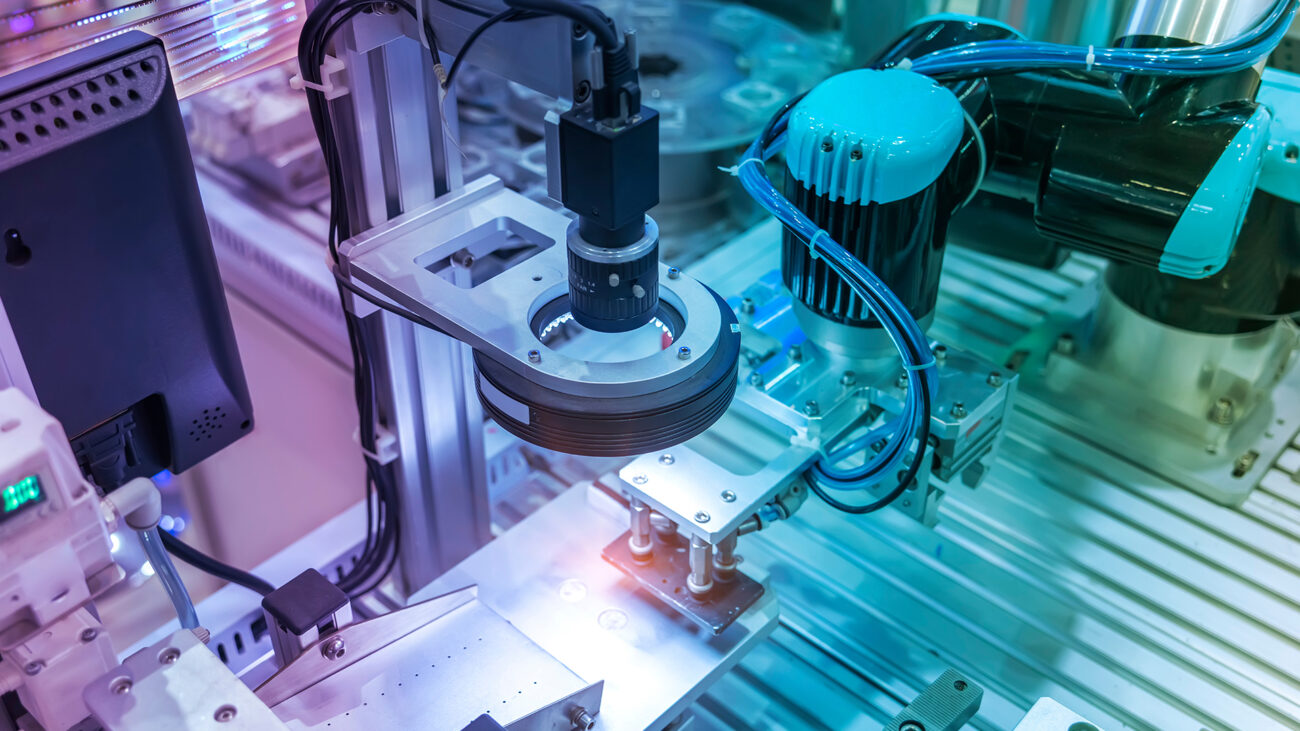

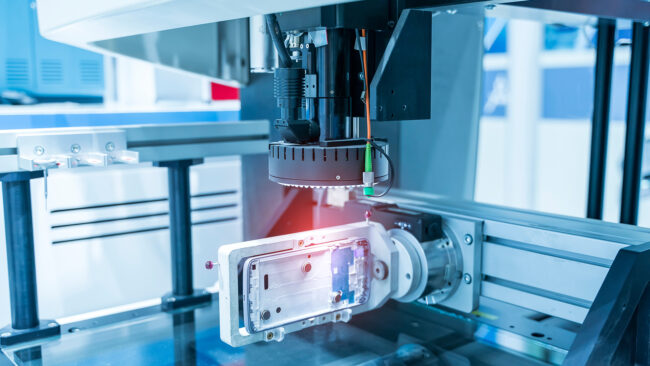

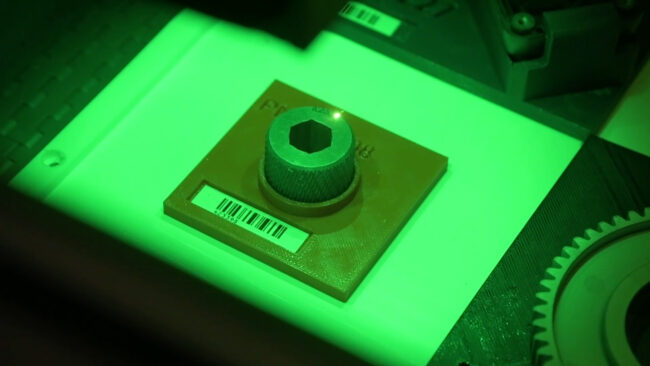

High-speed inspection systems utilize advanced sensors, cameras, and artificial intelligence (AI) algorithms to detect defects and deviations in real-time. These systems can quickly identify imperfections that may go unnoticed in manual inspections. This level of accuracy ensures that only products meeting stringent quality standards make it to the market, reducing the risk of recalls and warranty claims.

Increased Efficiency:

By automating the inspection and sorting process, manufacturers can dramatically increase the speed at which products move through the production line. This not only reduces bottlenecks but also allows for higher production volumes without compromising quality. Consequently, manufacturers can meet customer demands more efficiently and cost-effectively.

Cost Savings:

High-speed inspection systems can significantly reduce labor costs associated with manual inspections. These automated systems work tirelessly around the clock, eliminating the need for breaks and minimizing human errors. Additionally, they can sort and reject defective products in real-time, preventing costly rework and scrap.

Data-Driven Decision Making:

Modern inspection systems generate vast amounts of data during the inspection process. Manufacturers can leverage this data to gain valuable insights into their production processes. By analyzing trends and patterns, they can identify areas for improvement and fine-tune their operations to achieve optimal efficiency and quality.

Customization and Flexibility:

High-speed inspection systems are highly customizable to suit the unique needs of different manufacturing processes. Whether it’s inspecting food products, electronics, or automotive components, these systems can be tailored to meet specific industry requirements, ensuring that no defects slip through the cracks.

Regulatory Compliance:

In industries with strict regulatory requirements, high-speed inspection and sorting systems can help manufacturers meet compliance standards consistently. These systems can provide documentation and reports that demonstrate adherence to quality and safety regulations.

Case Study: Automotive Industry

One of the most notable examples of the successful implementation of high-speed inspection and sorting systems is in the automotive industry. Car manufacturers rely on these systems to inspect and sort components such as engine parts, electronics, and body panels. By using AI-driven cameras and robotic arms, they can quickly detect defects like scratches, dents, or misalignments. This not only ensures the safety and reliability of vehicles but also optimizes production efficiency.

High-speed inspection and sorting systems represent a transformative leap forward in manufacturing. They offer a powerful combination of precision, speed, and adaptability, making them invaluable tools for ensuring product quality while maximizing efficiency.

In today’s competitive landscape, manufacturers who embrace these technologies are better equipped to meet customer demands, reduce costs, and stay ahead of the curve. As the manufacturing industry continues to evolve, high-speed inspection and sorting systems will undoubtedly play a central role in shaping its future.