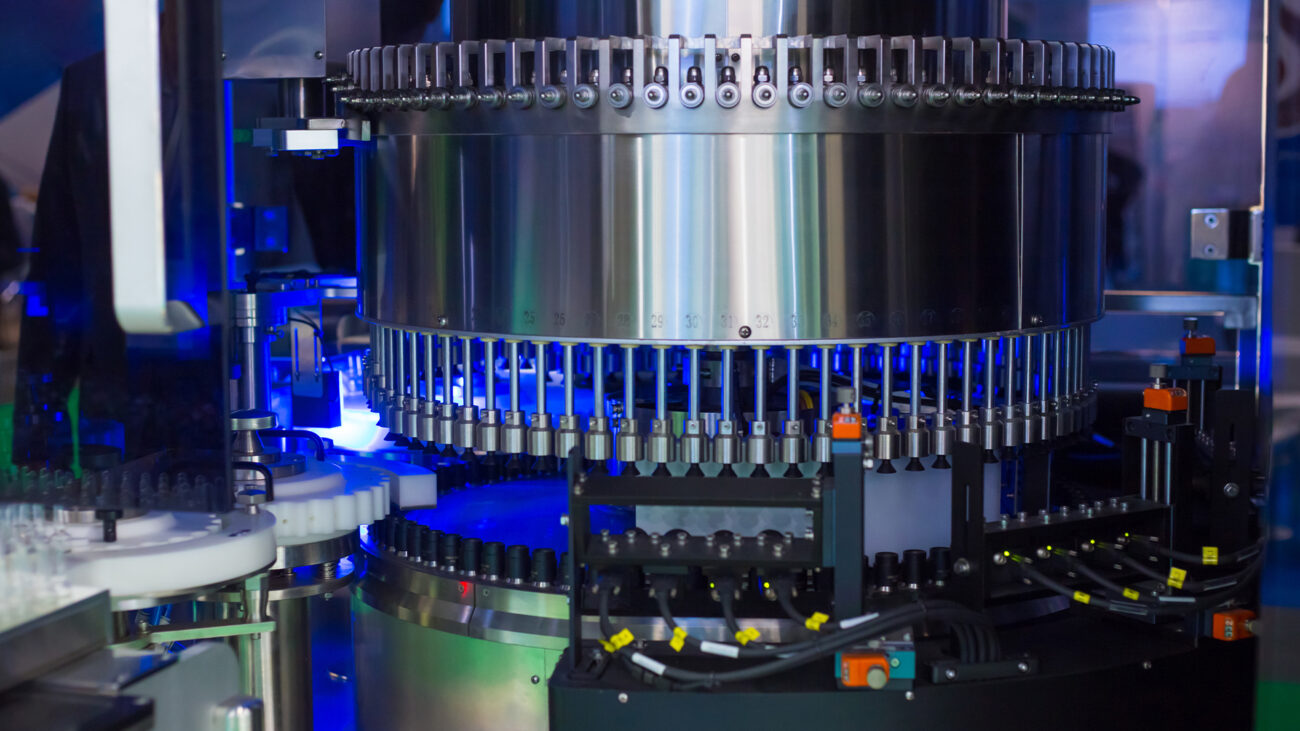

Rebuilding inspection machines requires meticulous attention to detail and a thorough understanding of the latest technological advancements.

In the dynamic landscape of automation and inspection, the ability to innovate and adapt is paramount. As an automation and inspection company, the prospect of revitalizing older, imported inspection machines with locally sourced parts and support not only presents a cost-effective solution but also underscores a commitment to sustainability and self-reliance.

Bridging the Gap with Local Expertise

Robust, imported inspection machines have long been a cornerstone of the industry. However, the challenge of obtaining spare parts and technical support can hinder operational efficiency and sustainability. By leveraging locally sourced components and support, companies can bridge this gap, ensuring seamless operations and mitigating potential downtime.

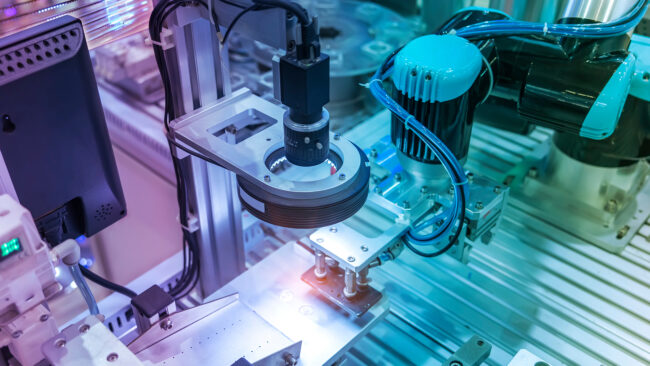

1. Tailored Upgrades for Optimal Performance

Every machine has its unique requirements, and retrofitting imported inspection machines with locally sourced parts allows for tailored upgrades that align with specific operational needs. With a thorough understanding of the intricacies of the machines and the capabilities of locally available components, companies can optimize performance, enhancing the accuracy and efficiency of inspection processes.

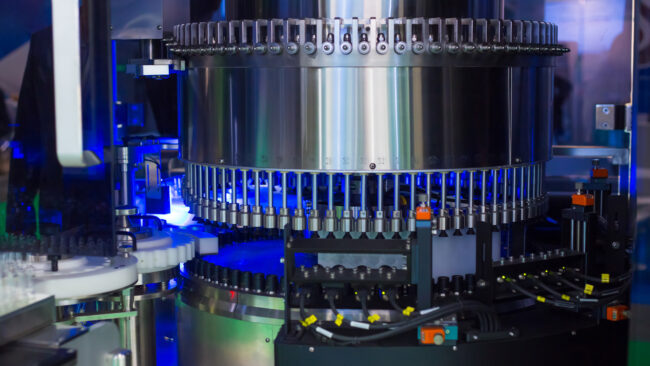

2. Cost-Effective Solutions for Long-Term Sustainability

The reliance on imported parts often comes with hefty costs and extended lead times. Embracing locally sourced components not only reduces expenses but also expedites the maintenance and repair processes. This shift to rebuilding inspection machines and utilizing local resources promotes sustainability, fostering a self-reliant approach that contributes to the growth and stability of the local economy.

3. Strengthening the Local Industrial Ecosystem

Investing in local parts and support strengthens the local industrial ecosystem. Collaboration with nearby suppliers and technicians fosters a sense of community, promoting knowledge transfer and skill development. This collaborative approach not only bolsters the company’s operations but also contributes to the growth and advancement of the broader industrial landscape.

4. Enhanced Flexibility and Customization

Local sourcing enables greater flexibility and customization options. Companies can adapt quickly to changes in market demands, technological advancements, and regulatory requirements. With the support of local experts, they can explore innovative solutions and implement modifications that cater to specific industry needs, ensuring that the inspection machines remain at the forefront of technological advancement.

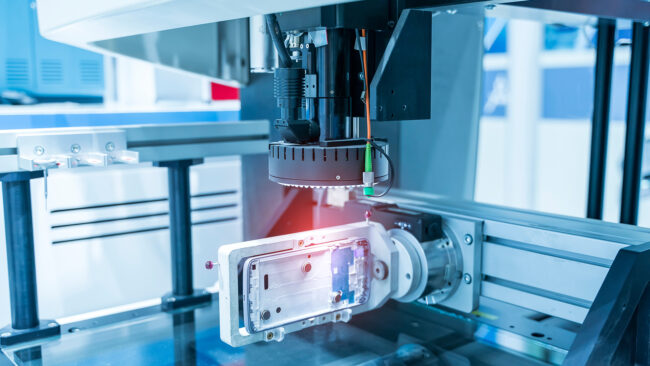

5. Sustainable and Reliable Maintenance Support

Local support ensures timely and reliable maintenance assistance. By establishing a network of local service providers, companies can guarantee swift response times and effective problem resolution. This proactive maintenance approach enhances the longevity of the inspection machines, minimizing operational disruptions and maximizing overall productivity.

The transformation of older, imported inspection machines through the integration of locally sourced parts and support represents a significant step towards sustainability, self-reliance, and community development. By embracing this approach, automation and inspection companies can not only optimize operational performance and cost-efficiency but also foster a resilient and thriving local industrial ecosystem.

As the industry continues to evolve, this commitment to local collaboration and innovation will be the driving force behind sustained growth and success.